Orders -> in case of re-sorting by supplier

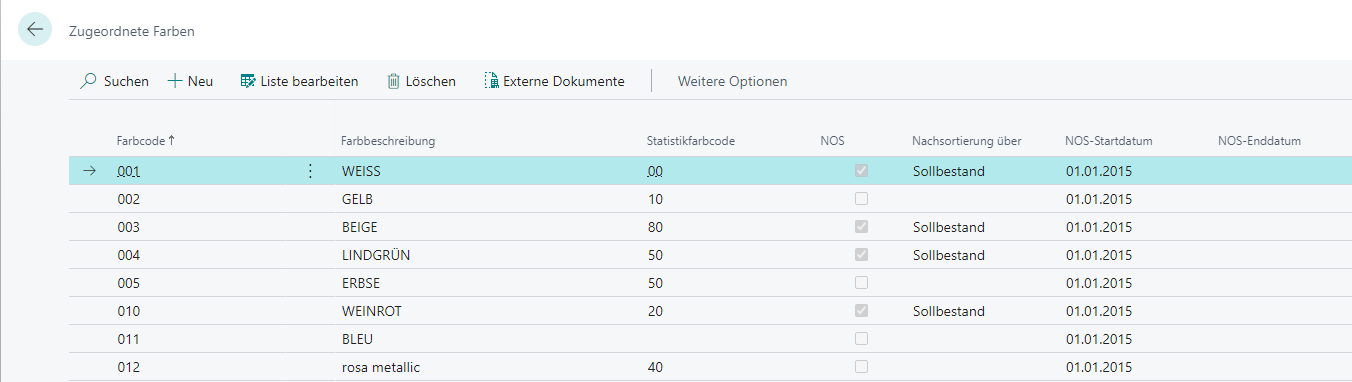

Controllable per item color

--> can be taken from the article as a default

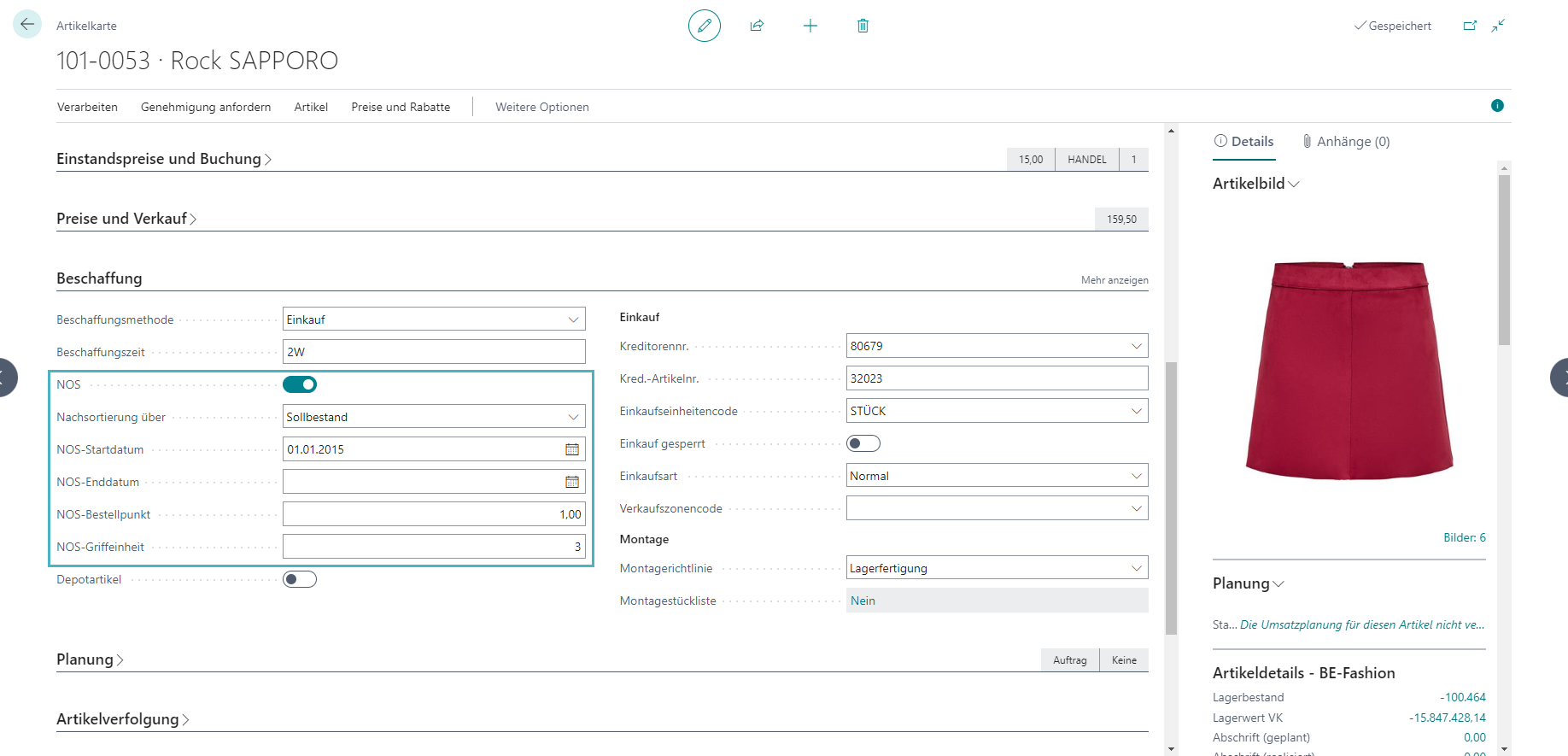

One order point and one NOS handle unit (quantity) can be stored per item

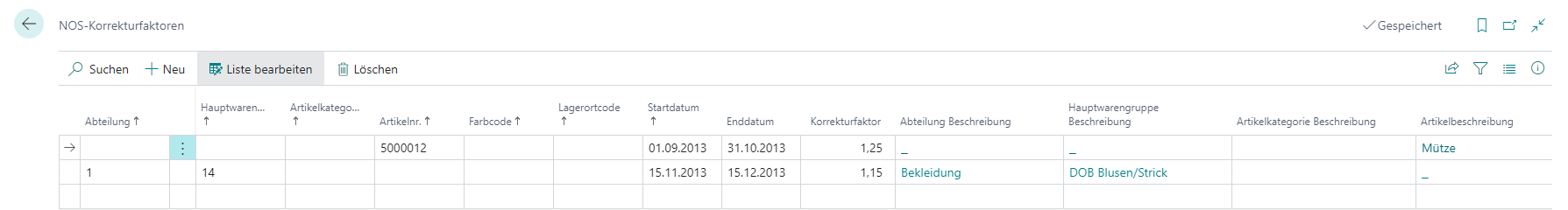

NOS correction factors can be defined with time reference at all levels of the article hierarchy, except for the article color level. The storage location is optional.

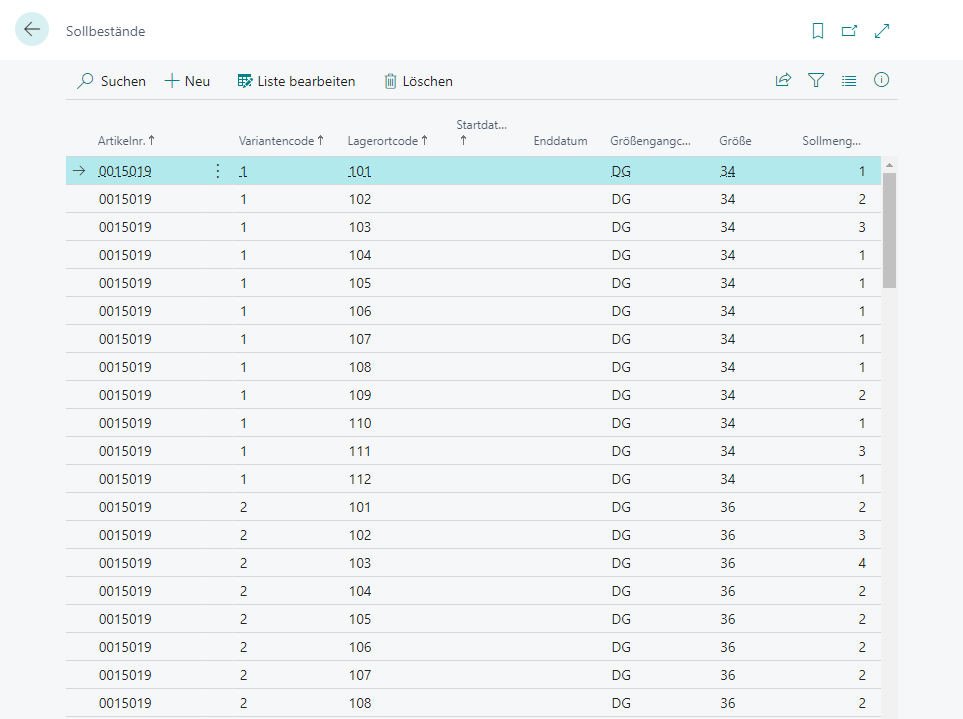

Target stocks are stored at SKU and store level. A time reference is available.

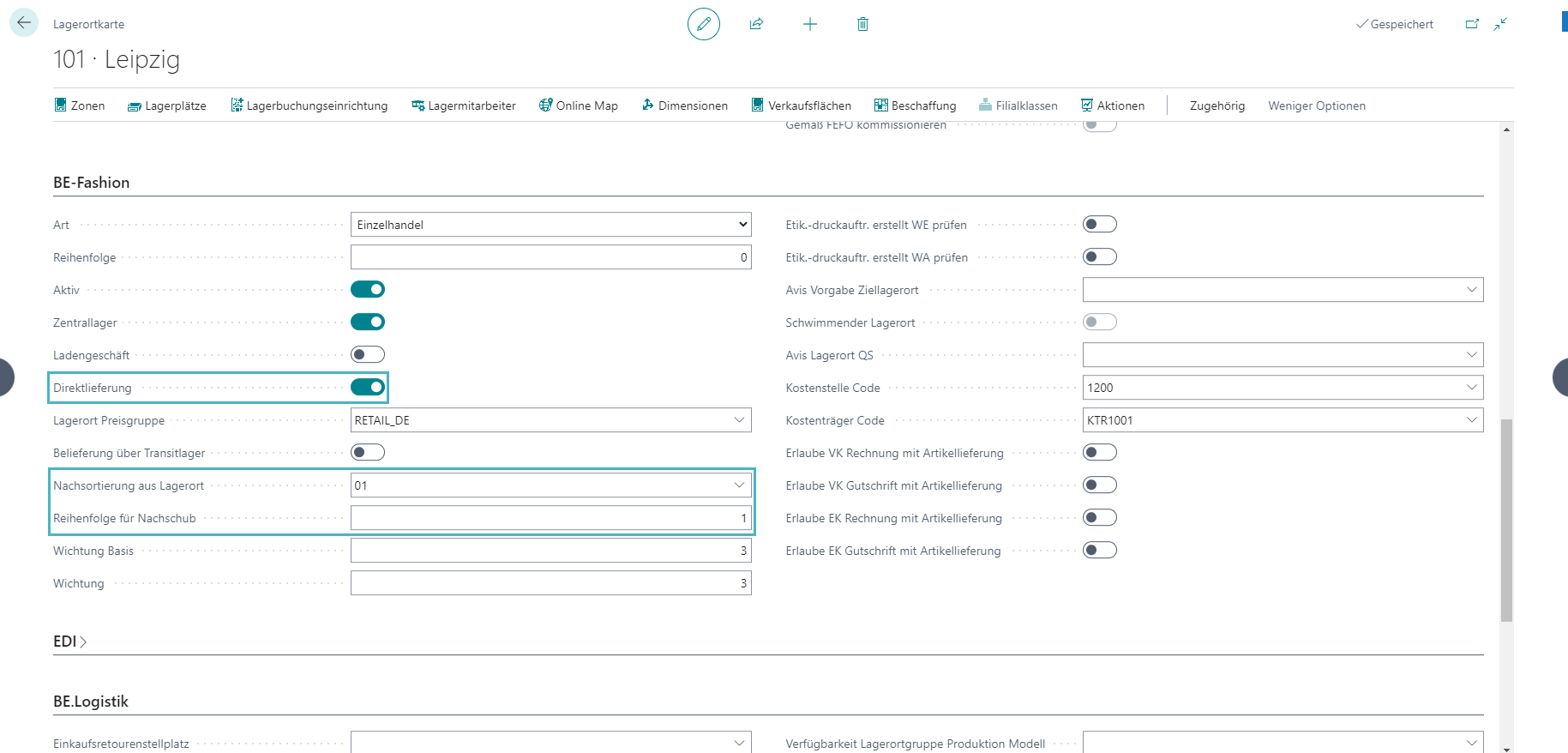

To be deposited per branch:

Order of replenishment

When resorting to target quantities, take into account:

The following information can be stored for each item color: NOS, Sorting Via, NOS Start/End Date.

If article colors are added, this information can be taken from the article as a suggestion.

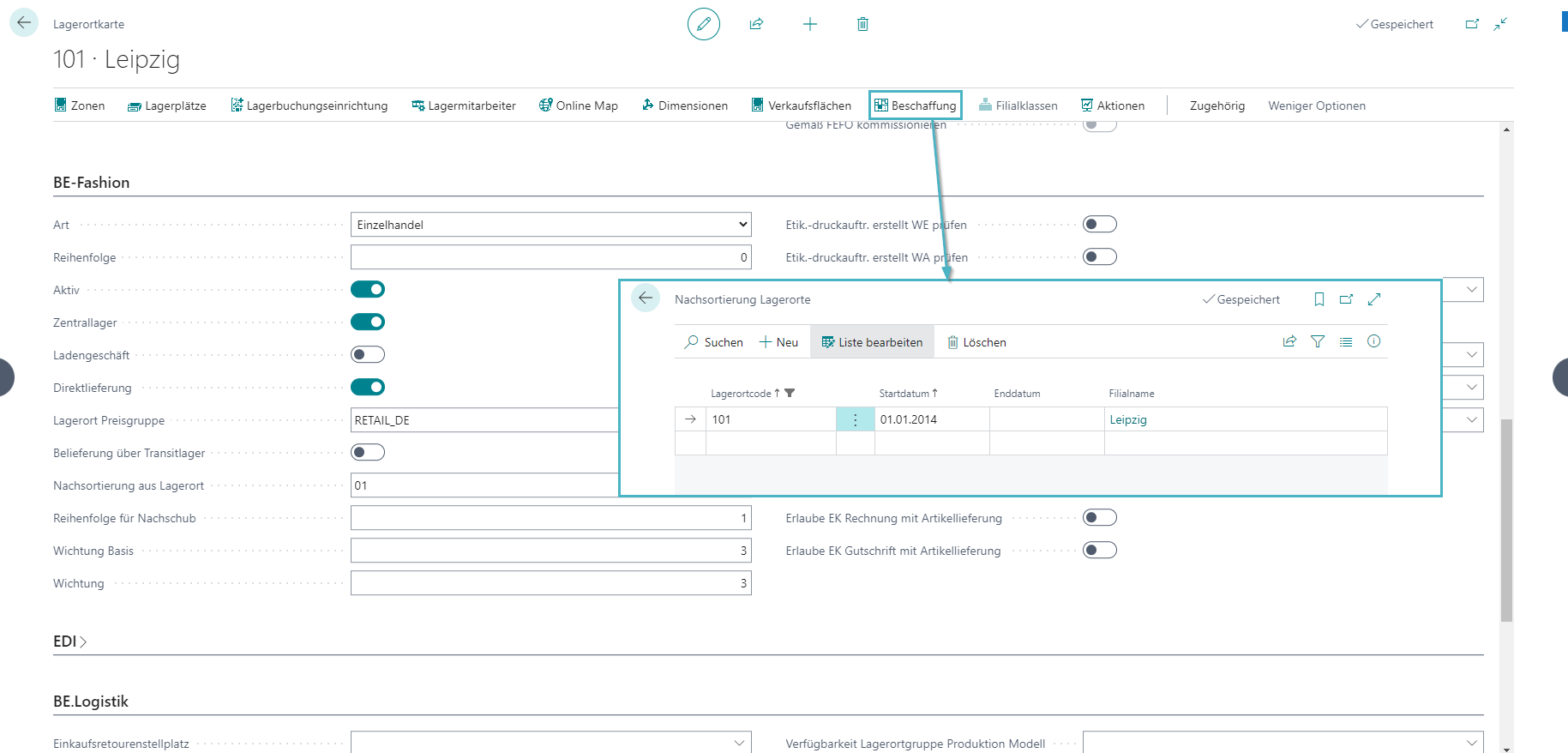

For each branch, it is possible to control whether and how the re-sorting should take place.

For each branch, it is possible to control the time of whether a re-sorting should take place. An end date does not necessarily have to be specified.

The target quantities are stored per SKU and storage location. A time reference is available, although an end date does not have to be specified. The maintenance and recording of the target quantities can be carried out via the matrix "Articles by Colors and Sizes".

NOS correction factors can be stored in the system to change the target quantities "temporarily". The correction factors can be specified on all 3 levels of the goods hierarchy plus the item color.

The storage location is optional.

The correction factor is searched for per store "from fine to coarse". If nothing was found, the search is repeated with branch = empty.

The correction factor can be greater than or less than 1:

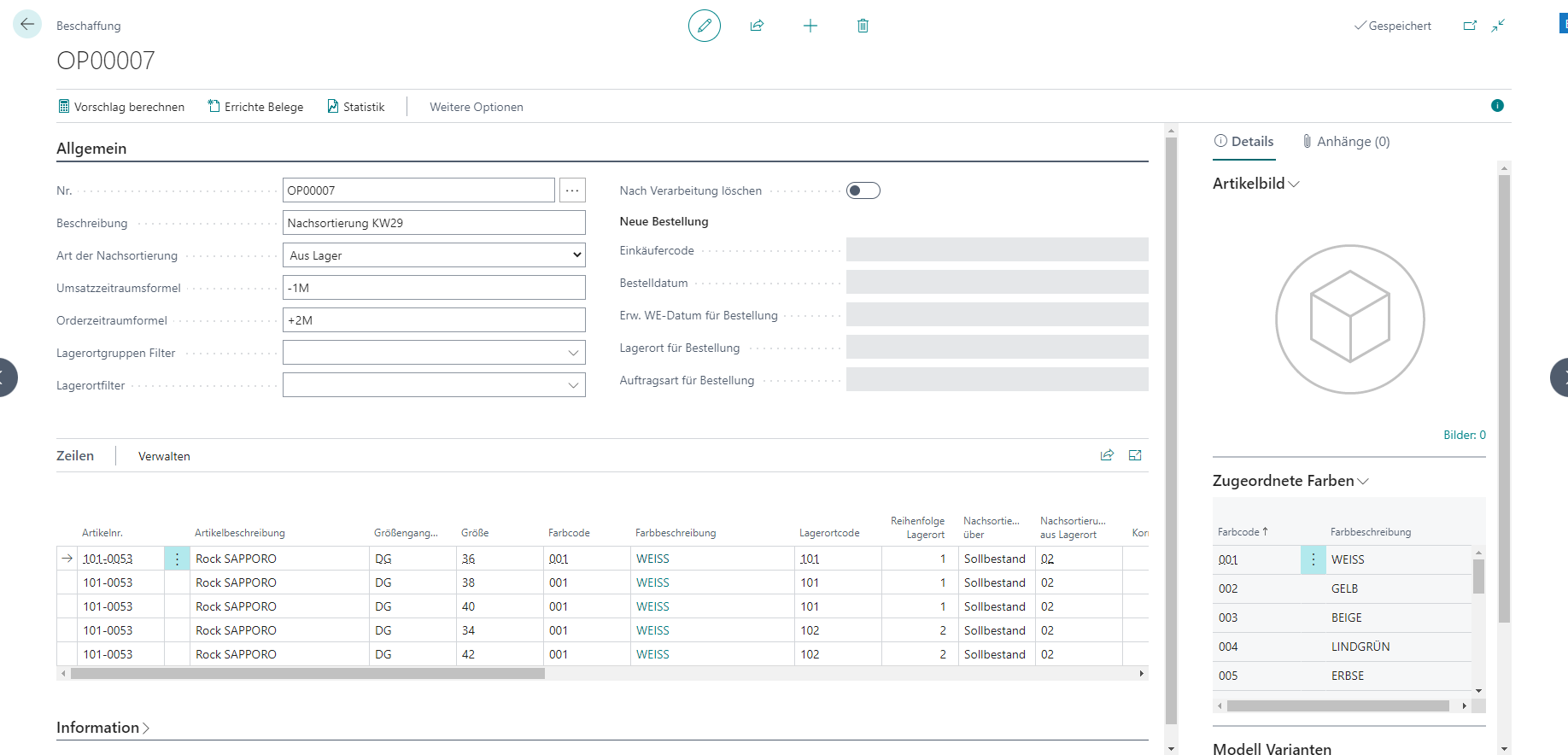

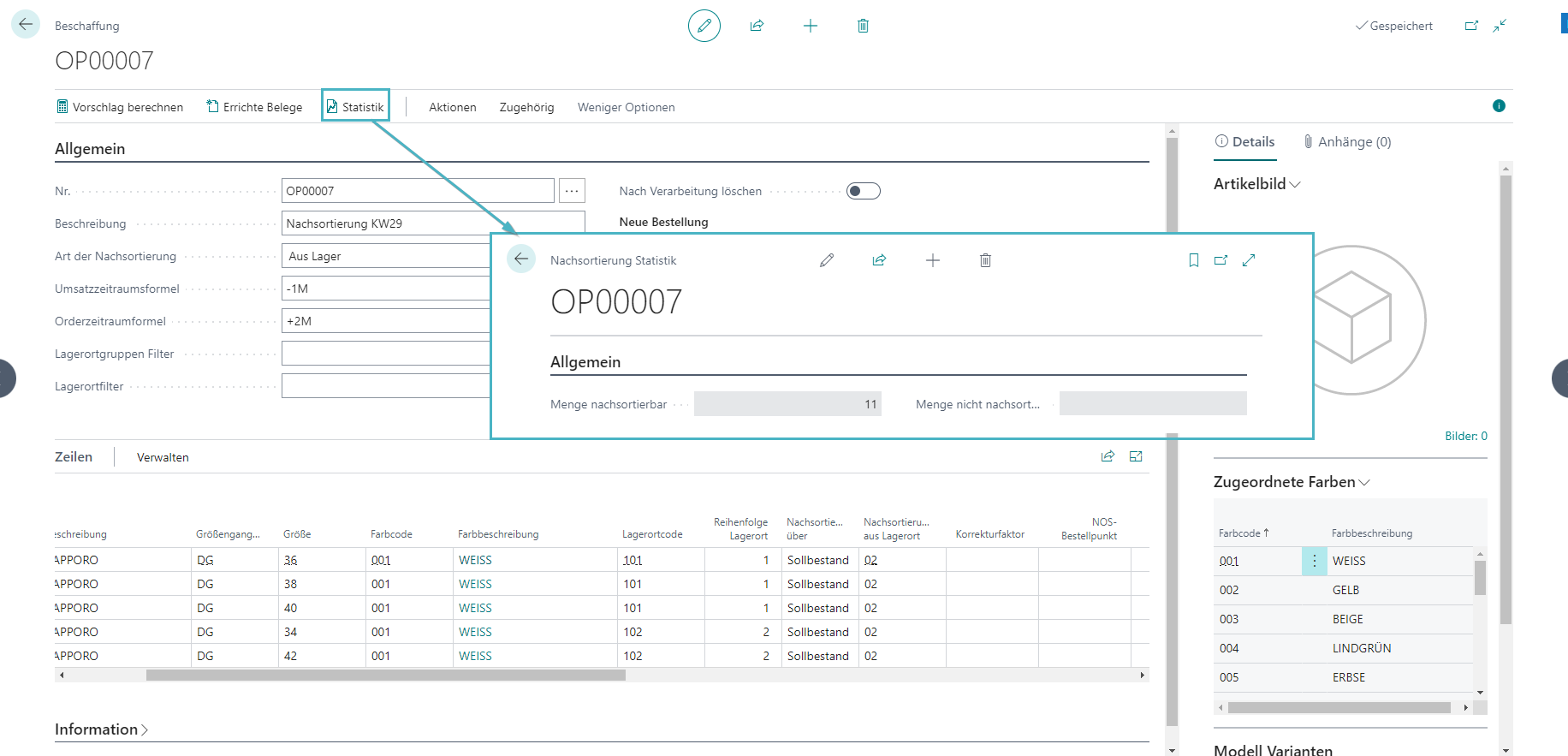

Subsequent sorting document with the following information:

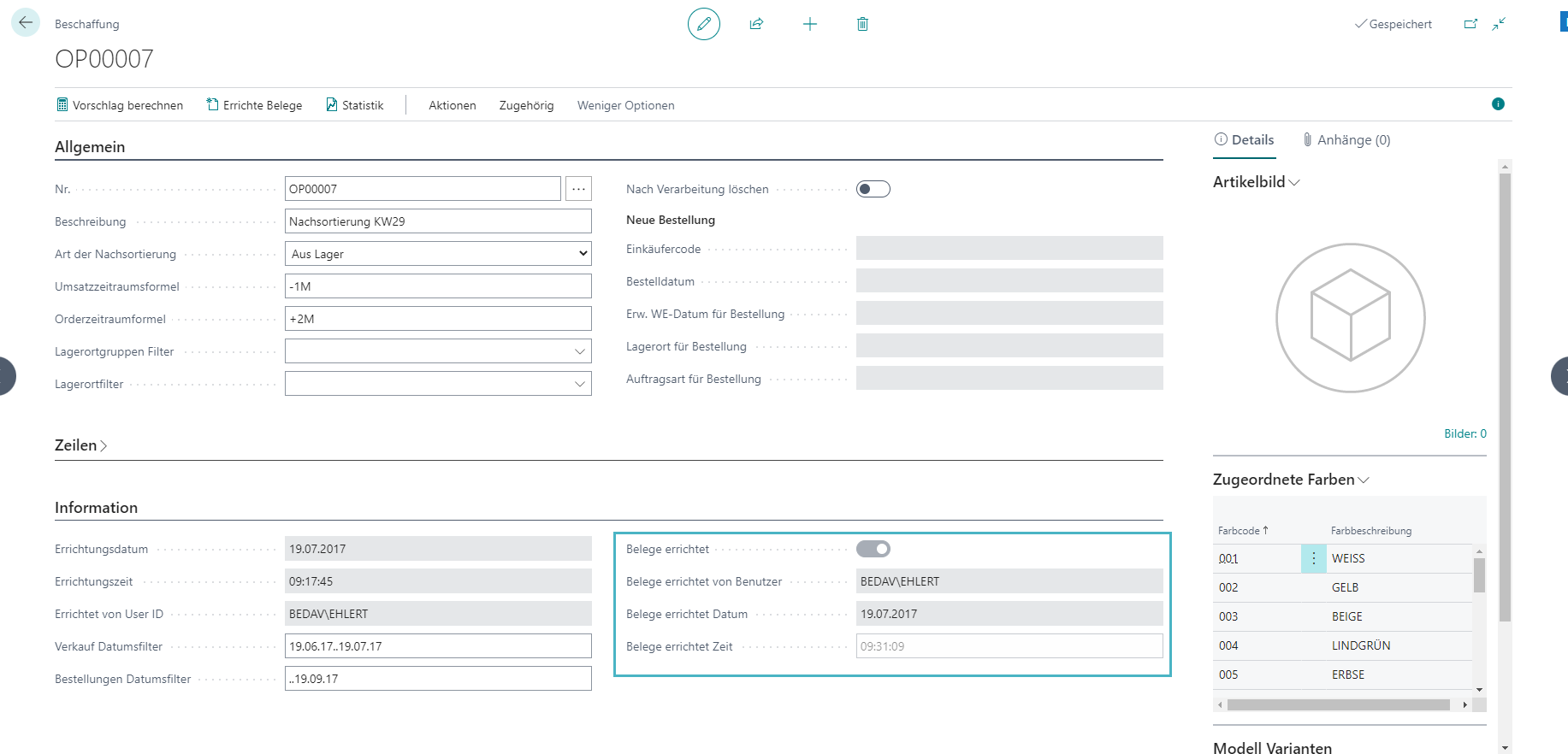

Delete after processing: If the rows are to be deleted after the document has been created.

In the case of the "Create Purchase Order" type of resorting, the following information can be specified as the default for the purchase orders to be created:

Order type

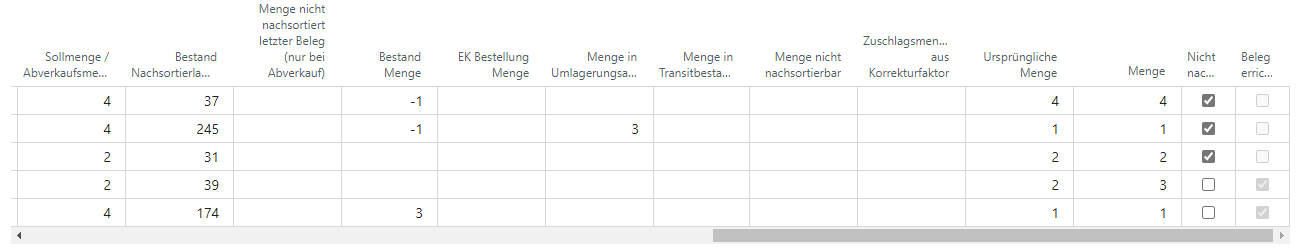

When resorting to target quantities, take into account:

The suggestion of reordering takes into account the order of the stores for replenishment (relevant if stock from which reordering is to be reordered is not sufficient).

The quantities can be adjusted.

NOS Handle Unit:

The NOS handle unit (stored on the article) indicates whether an integer multiple is to be sorted by.

The quantity calculated by the system is rounded up if necessary.

NOS Ordering Point: The NOS reorder point (stored on the article) specifies the quantity from which a re-sorting is to be triggered.

The statistics call can be used to display how many quantities were re-sortable or not.

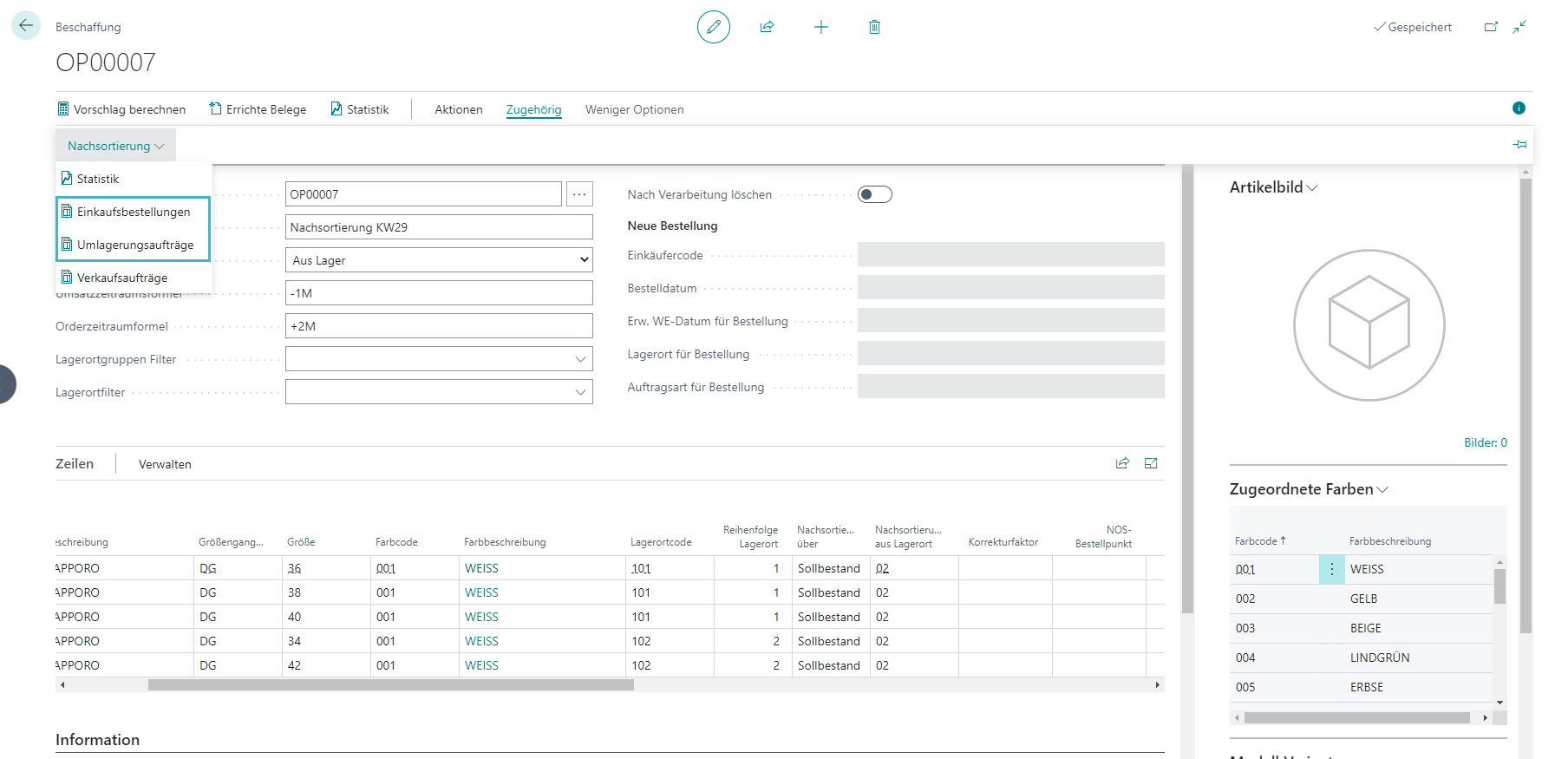

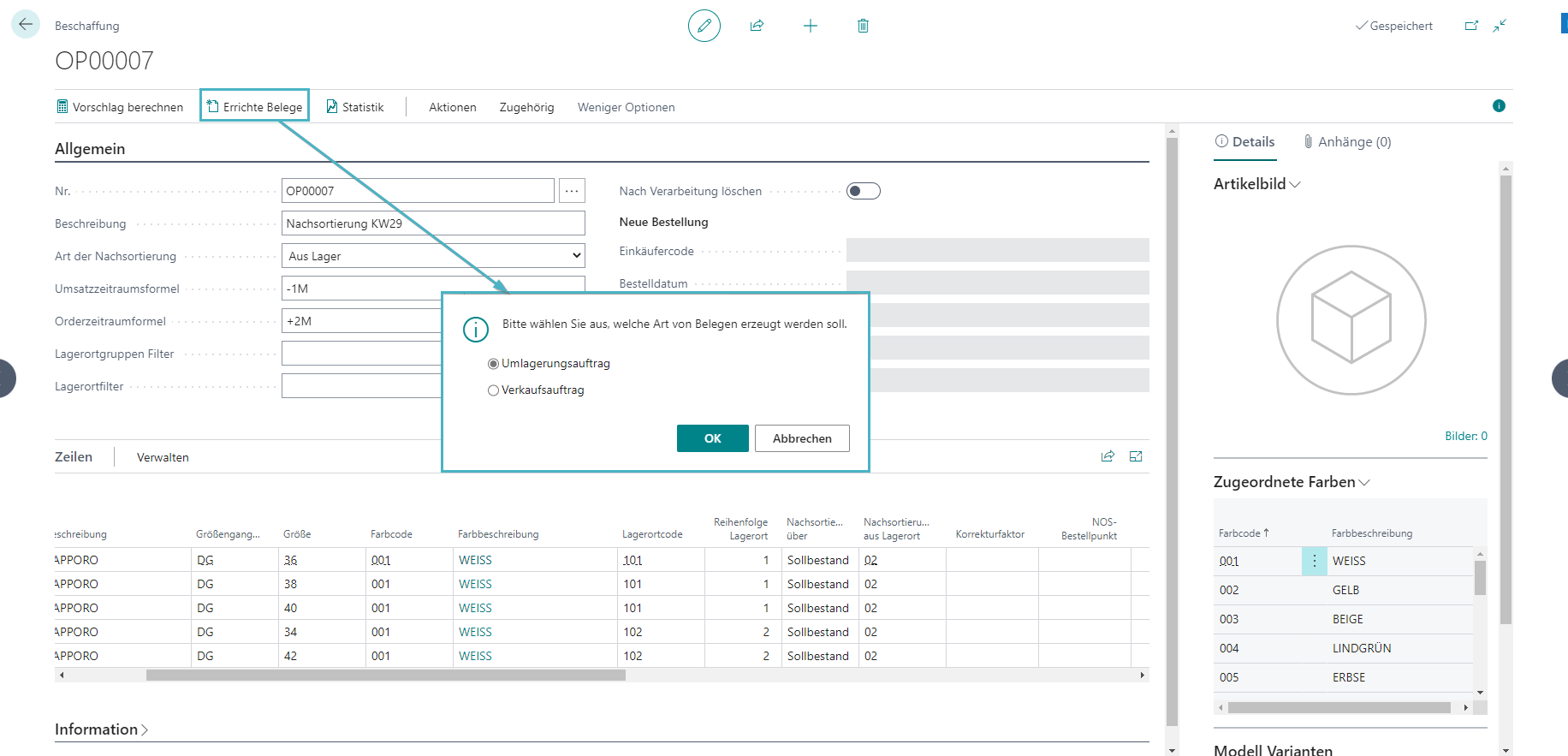

Depending on the type of resorting, the Create Documents function creates purchase orders or transfer orders per storage location.

The re-sorting document stores when/who created the documents.

If sales quantities cannot be sorted due to a lack of central stock, they are stored and taken into account in the next run.

Directly from the reordering document, you can navigate to the created purchase orders or transfer orders.