Measurement tables

Description

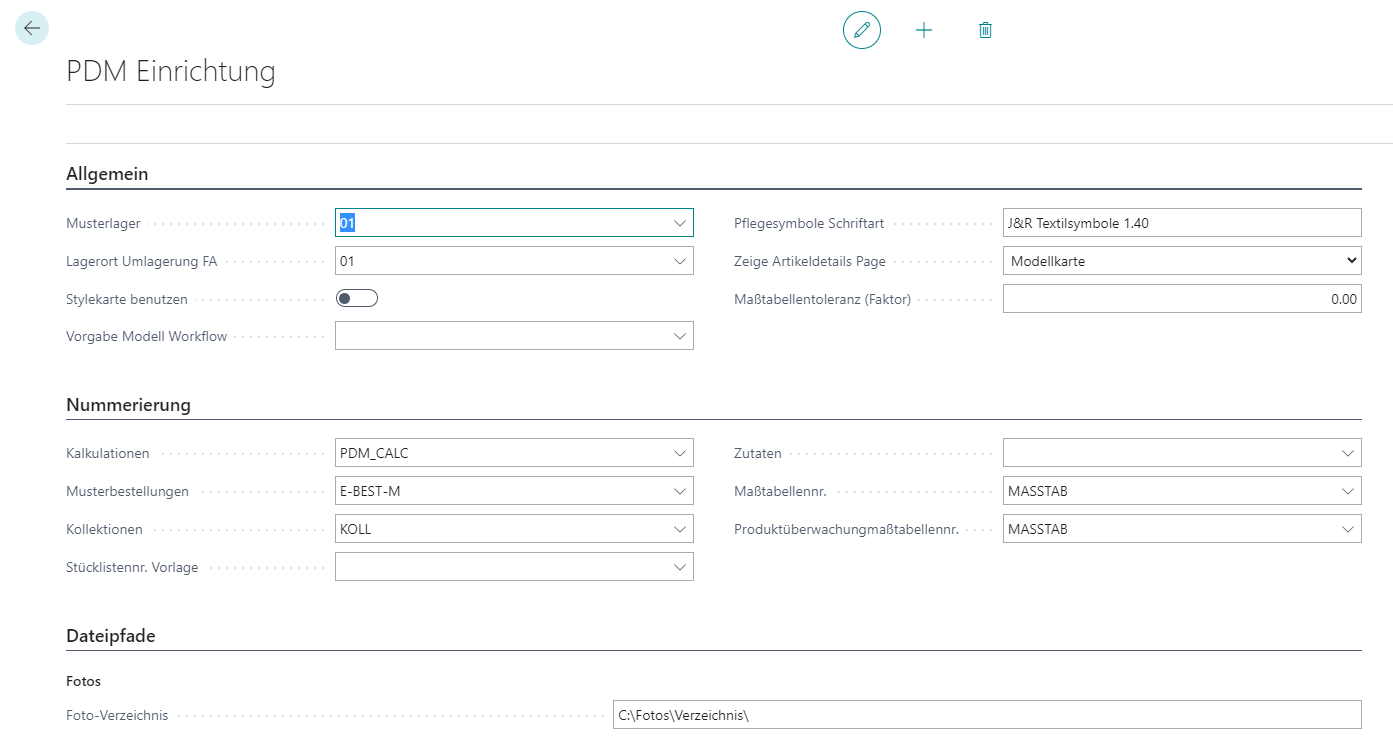

PDM Setup

Definition of number series per dimension chart type (layout and product monitoring).

Definition of general dimensional tolerance (factor) for calculation of tolerances at runtime from the dimensions per jump point.

Measurement Table Templates

Improved storage of size information. Until now, sizes have always been drawn from size range (inconsistency possible).

Design Measurement Table

Dimension tables (draft) can be linked to a model as often as you like, regardless of the previous primary key (article number, size range).

The 1:1 became a 1:n link between the measurement table and the model.

Dimensional tables (draft) can be extended as desired:

- Only the existing sizes of the article are now copied from the template (e.g. template XXS -> XXL, article has only XS -> XL)

- Insert new dimension points with corresponding jumps.

- Modifying jump points for a specific item to deviate from the template

- Jump 0 is accepted if the reference value contains a value

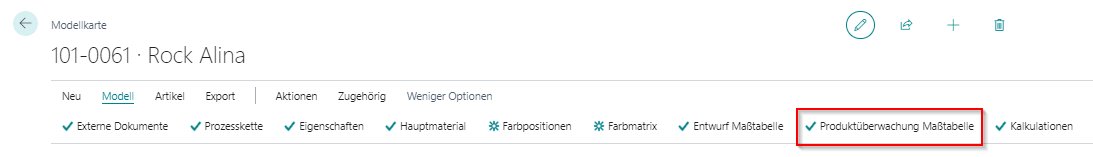

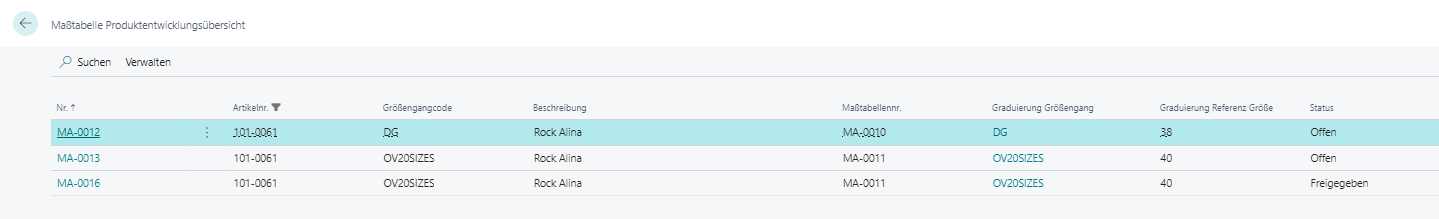

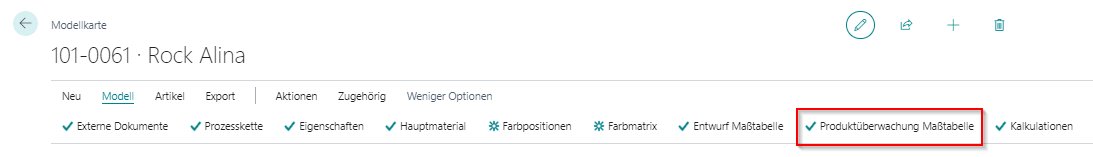

Product Monitoring Measurement Table

Measurement table (product monitoring) to check different measurement tables.

- Since there can be different versions of the dimension table (draft), a 1:n link to the model is also necessary in product monitoring. For each product monitoring, the underlying measurement table can be used.

- Product monitoring itself is no longer used to record sample parts to be measured, but only to evaluate them

- Product monitoring is independent of column headings based on patterns. Column headings are defined by pattern type in the completed journals that are assigned to product monitoring.

- Journals are subordinate documents for product monitoring

- Referring to the measurement table of the product monitoring, any number of control measurements can be carried out on all known sizes of the article (background e.g. a check of a complete size set)

- Entries can be commented on as well as the measurement table itself

- The values for product monitoring are taken over from the completed acquisitions and can be compared for each reference variable

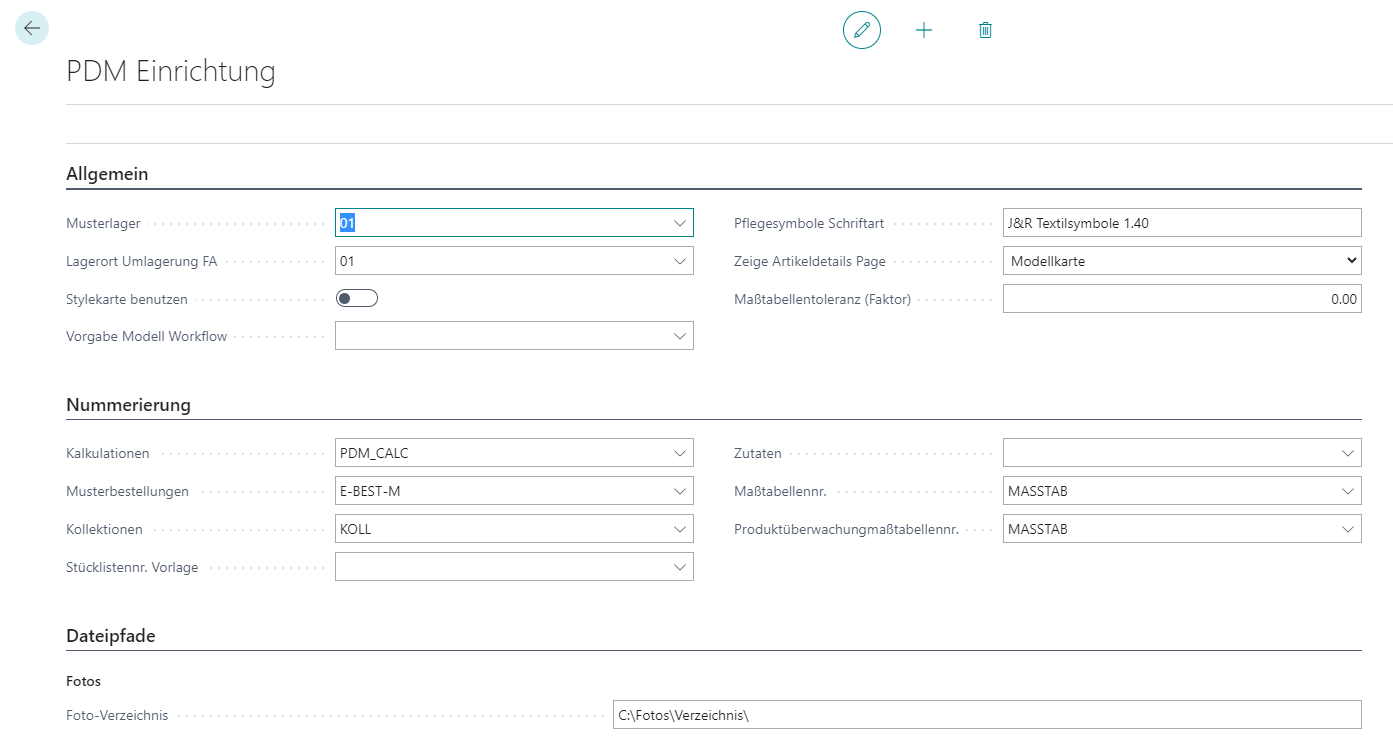

Setup

PDM Setup

Definition of number series for measurement table design and measurement table product monitoring.

Definition of factor to highlight tolerance exceedances, in case of deviation from jump points.

Measurement Table Templates

- Deposit in the menu

- PDM / Setup / Measurement Tables

- Attachment with template name and description

- Indication of the graduation size to which the template is to apply

- Definition of the graduation reference size from which the jumps are indicated

- Definition of tolerance for evaluating deviation from each jump in product monitoring

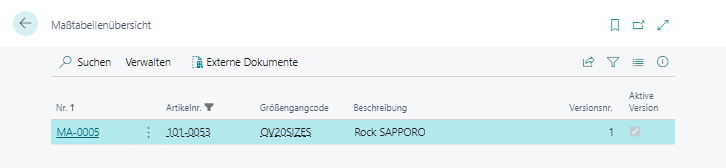

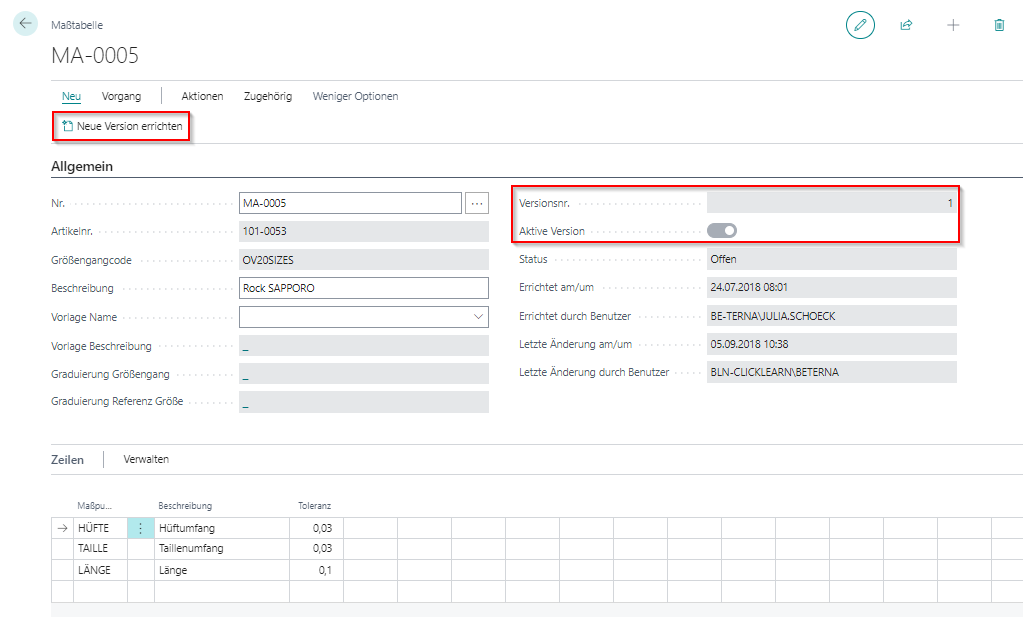

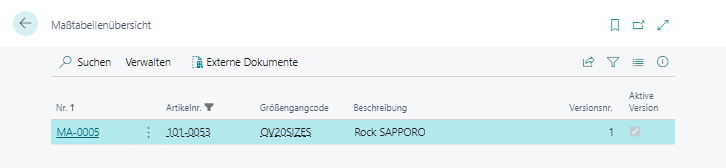

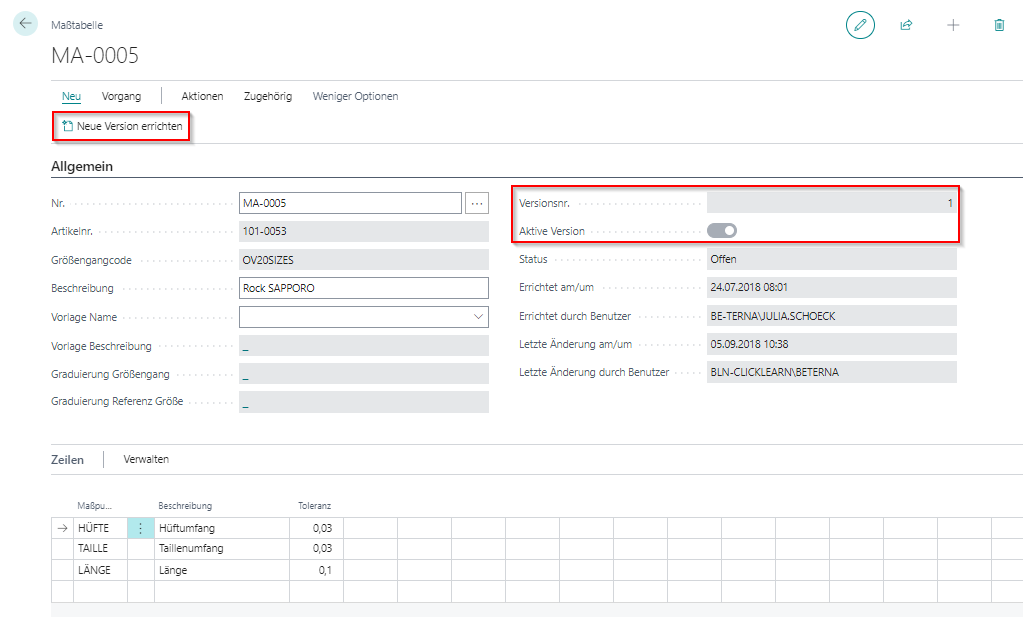

Design Measurement Table

Storage of custom-fit dimension tables incl. versioning

- Initial creation of dimension tables via model map or model overview

- Establishment of a measurement table for each combination of item no. and size range

- The primary key is a document number that can be set up.

- Versioning of the dimension tables from the original version 1 and marking of the active version for automatisms

Storage/derivation of further versions from a created dimension table

- Transfer of the template for existing sizes on the item

- Creation and derivation of further versions

- Copy of the active version and modification of the measured values

- Definition of new measuring points that deviate from the template

- Definition of your own jumps that deviate from the template

- Use of Jump Value 0

Adoption of tolerance from the template

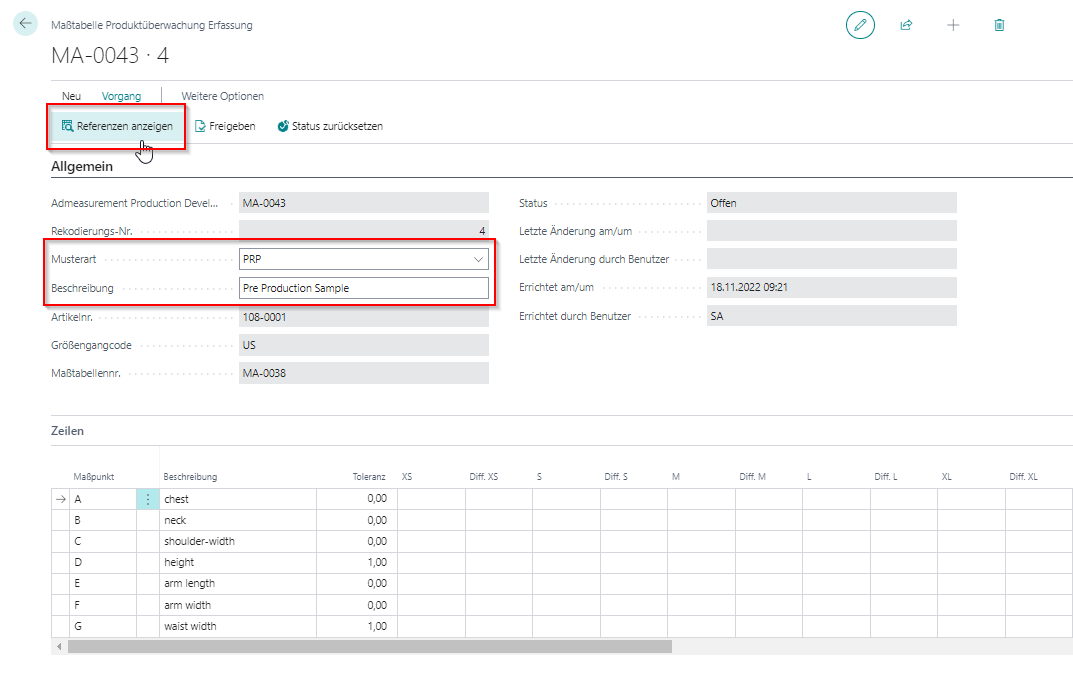

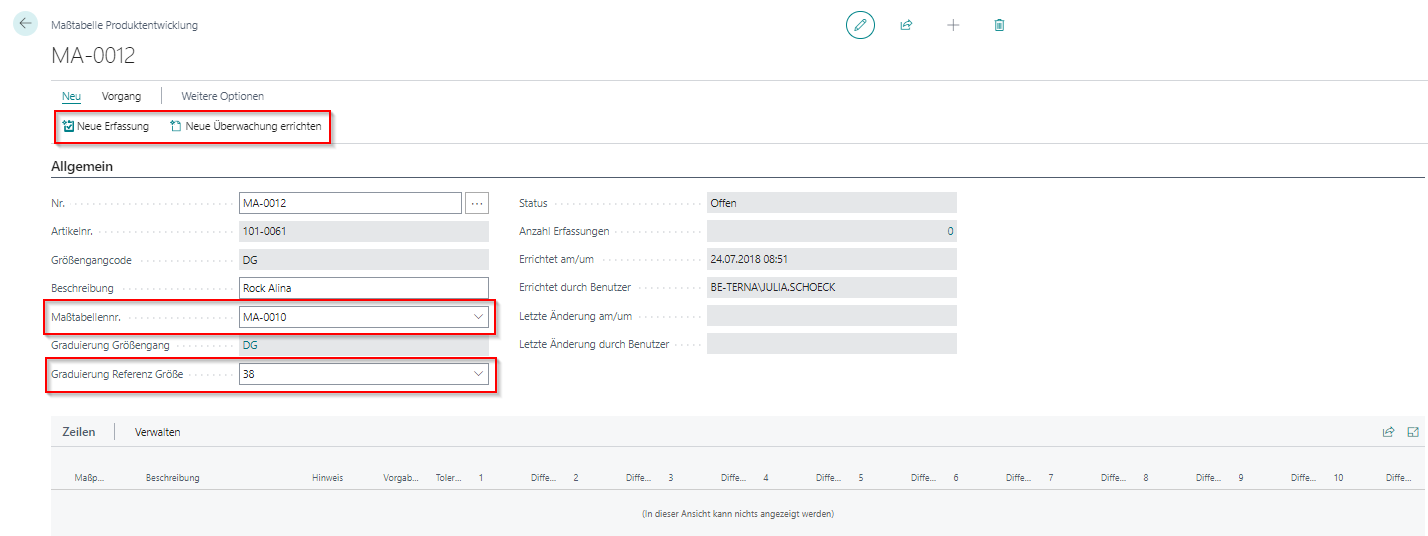

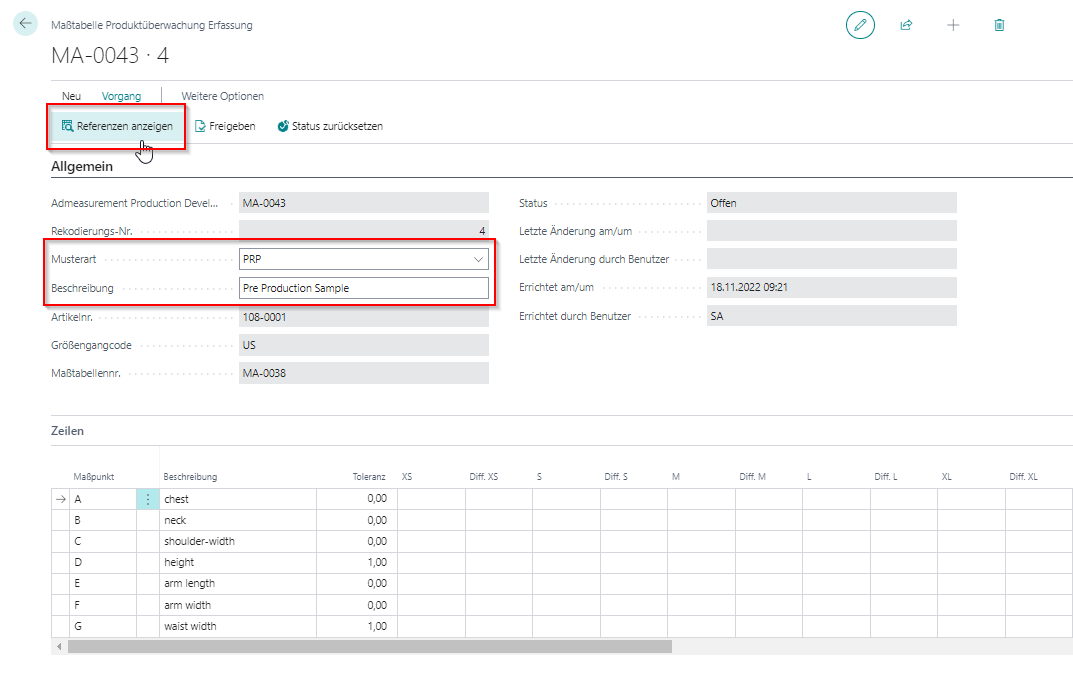

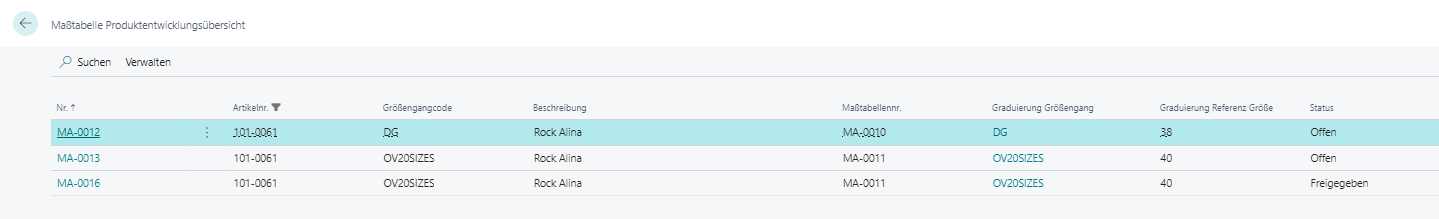

Product Monitoring Measurement Table

Deposit with reference to measurement tables

- Initial establishment of product monitoring measurement tables via model map or model overview

- Establishment of a measurement table for each combination of item no. and size range

- Primary key is configurable document no.

- Automatic storage of the active dimension chart version from the drafts

image.png

image.png

Comparative evaluation display

- Product Monitoring Measurement Table is used to overview and evaluate all measurements with reference to the underlying Measurement Table Design - No Input --> Update via "Update Monitoring"

- By changing the graduation reference size, it is possible to switch between the results of the individual measurements at the measurement point and size level in the rows

- The column headings no longer result from a static list, but depend on the pattern types in the stored entries

- The measurements themselves are carried out in the so-called recordings, which are linked 1:n to the product monitoring

- The product monitoring lines now result from the selected measurement table and no longer from the template --> possible extensions are thus transferred to monitoring

- If necessary, a new monitoring and assignment of a different measurement table can be created for an article/size

- Approval is only possible when the stored entries have been completed

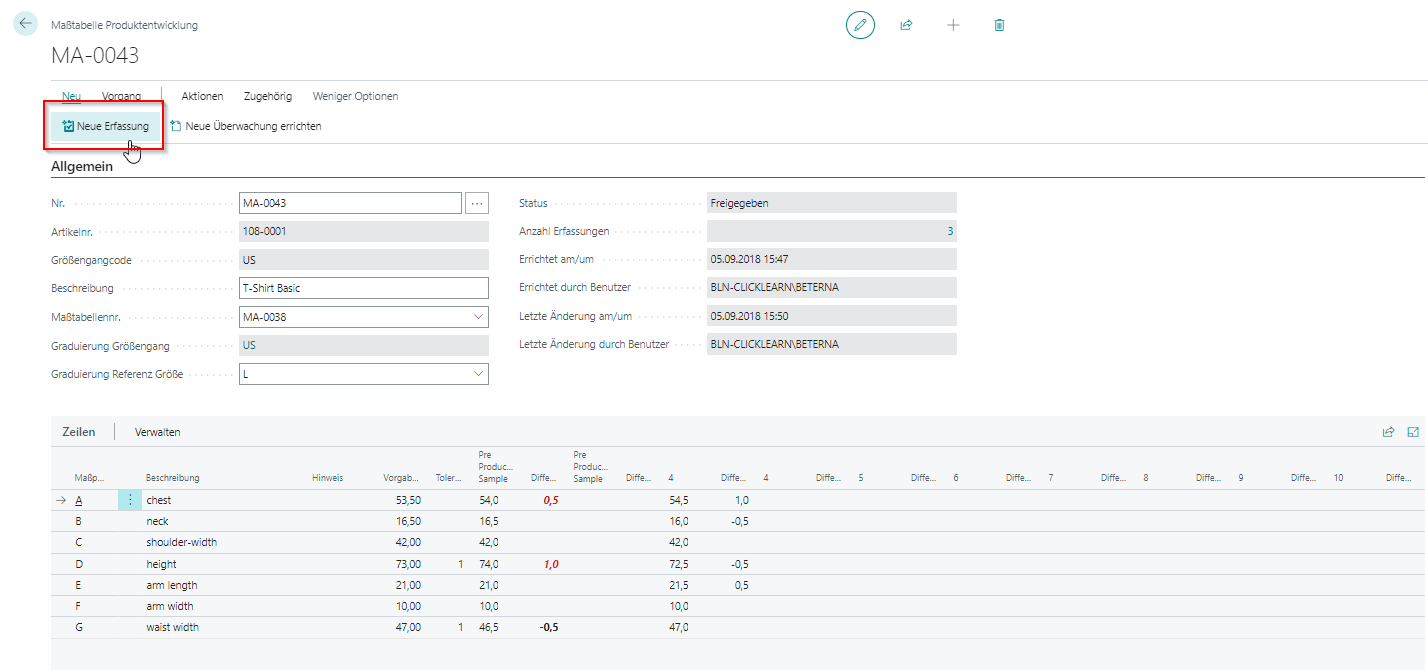

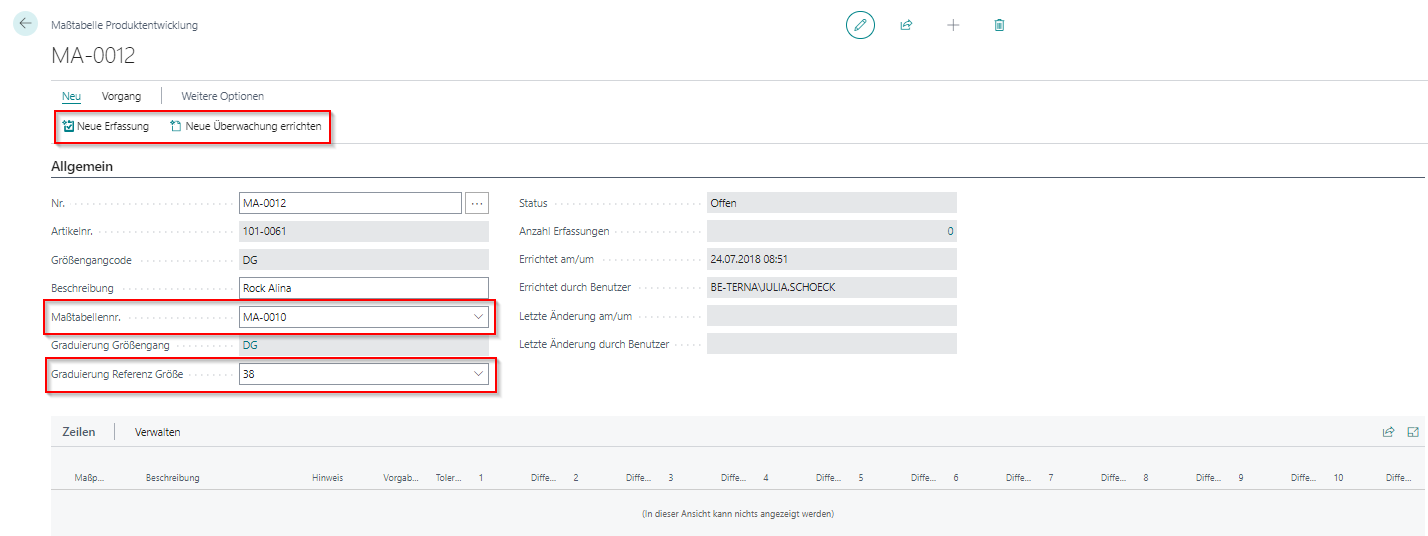

Acquisitions / control measurements with status

- Any number of entries can be created for each product monitoring measurement table

- Entries inherit the underlying product monitoring measurement table

- The measurements can be recorded for each size (you are no longer dependent on the stored reference size) --> supplier sends e.g. samples with size L instead of M or whole size set

- Journals must be marked Finished in order to appear in product monitoring

- Product audits can only be released when all related captures are finished

- Reference measurement can be displayed

- Storage of description texts and comments via editor

- Differences are highlighted

- No deviation = no formatting

- Deviation within tolerance = fat

- Deviation Out of Tolerance = Bold, Italic and Red

- If no tolerance for the jump point is defined in the template, the difference is compared with the size before and behind it and its deviation from the dimensional table tolerance (factor) (see PDM Setup).

image.png

image.png

image.png

image.png

image.png

image.png